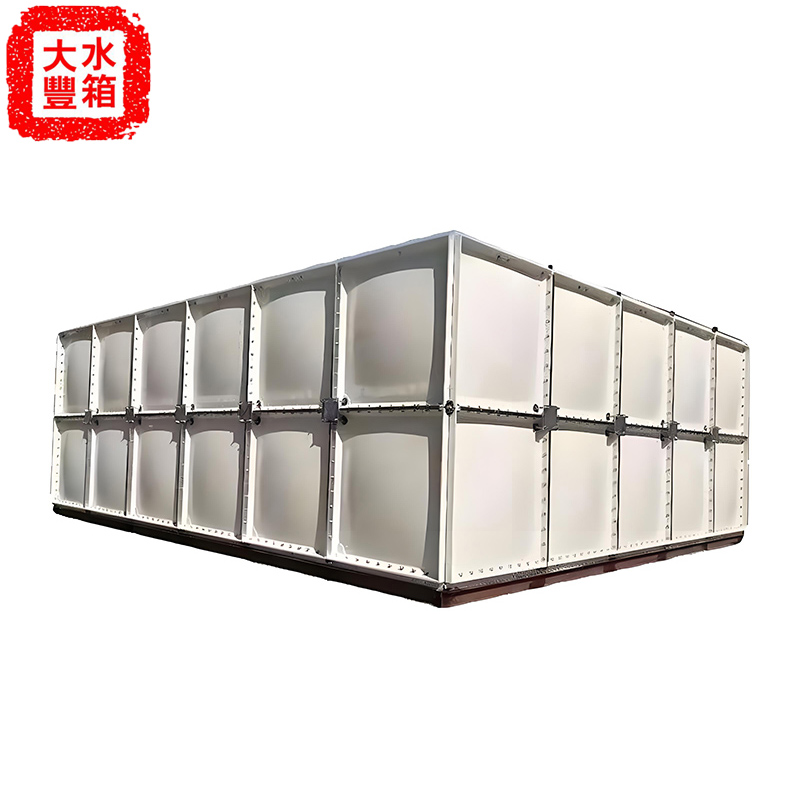

Fiberglass Water Tank

Basic information of set up of fiberglass water tank:

Firstly, earlier than construction, please comply with the basis necessities for concretefoundation.Secondly, at some point of the building process, it is integral to keep away from the use of hearth close to the watertank: defensive measures must be taken for the duration of welding operations to forestall sparksfrom splashing on the water tank plate.

Thirdly, for the comfort and protection of renovation and repair, a positive quantity ofspace ought to be left round the water tank.Fourth, do no longer contact the fiberglass molded board on sharp corners, and do no longer use equipment orother challenging objects to strike it.

Fifth, when putting in the water tank, go away a protection passage of ≥ 500mm betweenthe field and the wall, and the floor and the container need to be ≥ 500mmSixth.in the course of civil construction, guide need to be supplied first, and the connection jointsaround the fiberglass water tank and between the container panels must be Falling on thesupport pillar.

Precautions for set up of fiberglass: (If you want to save warm water or acidic or alkaline liquids, please specify earlier than putting an order.)

1. Fiberglass water tanks are commonly designed and manufactured for storing water at room temperature. Please do now not keep warm water and different liquids;

2. On web site construction: Before construction, please lay a stable basis in accordance to thedesign necessities of the drawings, and installation plan channel metal on pinnacle of thefoundation;

3. Assemble the container physique in accordance to the container board number, seal the single boards withrubber strips, improve them with bolts in the middle, and set up them horizontally;

4. Do no longer contact the sharp corners of the fiberglass molded veneer, and do now not use equipment orother challenging objects to strike it, in order to stop it from inflicting injurySingle boardrupture, water leakage and dew;

5. Add column tie bars interior the box, restoration and stability with bolts, and set up and debughorizontally as a lot as possible;

6. All water tanks have been mountedAfter completion, habits a unified inspection,adjustment, and water test. If there is no leakage, it is regarded qualified.

Attention to troubles at some stage in transportation of fiberglass water tanks:

1. To forestall the water tank from swinging out of manage in the course of lifting, a information ropeshould be tied to the water tank.

2. The water tank ought to now not fall or contact different objects to keep away from cracking of the structuralparts and interior corrosion-resistant layer of the water tank.

3. Fiberglass water tanks ought to no longer roll or slide on hard surfaces and must no longer collidewith components. The web site for storing water tanks ought to be flat.

4. Be cautious in the course of operation to stop tools, scaffolding, or different objects from hitting orfalling onto the water tank. functionWhen getting into the water tank, one need to wear tendersoled shoes. When the use of a ladder (inside or outside), any contact location with the water tankshould be improved to forestall floor scratches or nearby

loading.

5. When the use of a crane, the distance between the hook head and the water tank have to be at least equal to the distance between the lifting rings. use A constant distance rod connects the lifting ears parallel and perpendicular to the ground.

6. When the fiberglass water tank is no longer geared up with lifting rings, it is endorsed to use high-strength fabric straps or lifting rings at fantastic positions on each ends of the tank Lifting cable (diameter exceeding 25mm) for hoisting. When adjusting the function of the water tank with a forklift, the fork have to be cushioned.

7. Before installation, the fiberglass water tank must be positioned on a transport rack to prevent rolling due to wind or floor tilt.