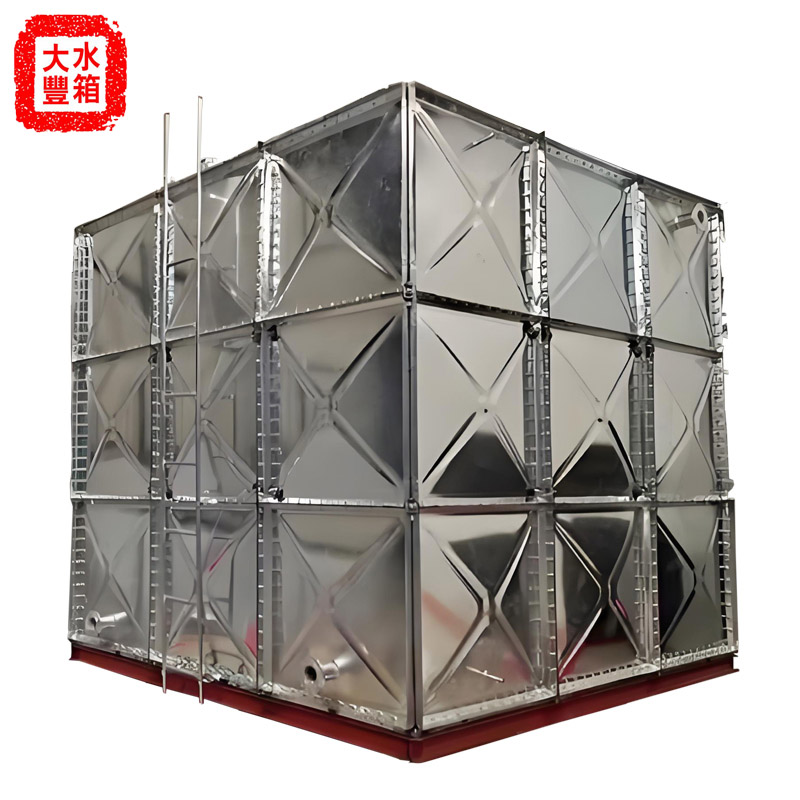

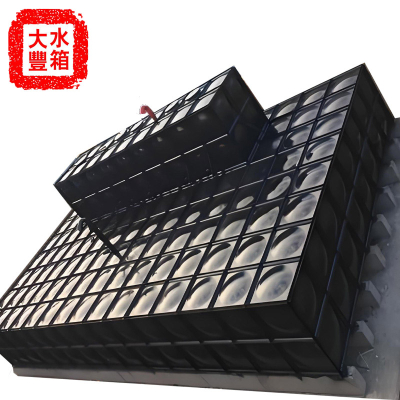

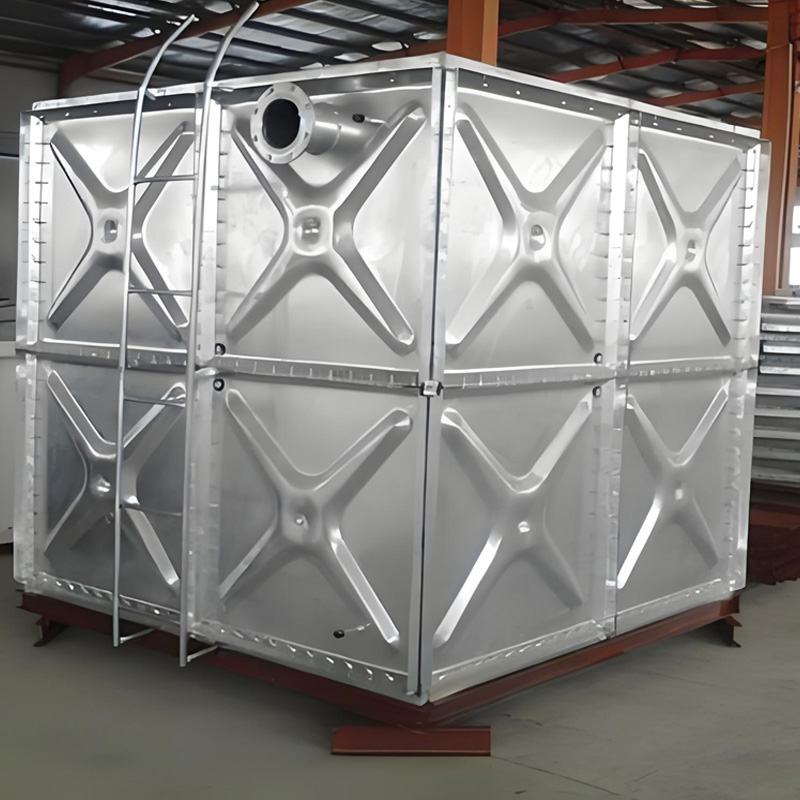

Galvanized Steel Plate Water Storage Tank

The production process of galvanized steel plate water tank:

The production of galvanized steel plate water tanks requires determining the design specifications of the water tank first. Select galvanized steel sheet materials with appropriate thickness according to the design. The quality of the purchased galvanized steel sheet should be checked to ensure it meets the standards. Use professional cutting equipment to cut steel plates into the required size. During the cutting process, it is necessary to ensure that the dimensional accuracy is within a very small margin of error. Polish the edges of the cut steel plate to prevent scratches. Then perform the bending operation of the steel plate to form the side plate of the water tank. The bending angle is strictly controlled according to the design requirements. The corner connection of the water tank is completed using welding technology.

Welding workers should possess professional qualifications and rich experience. Choose matching welding materials to

ensure quality during welding. Control the welding speed to ensure that the weld seam is uniform and firm. After welding is completed, the weld seam should be visually inspected for defects. Use non-destructive testing methods to inspect the internal quality of the weld seam. Promptly repair the detected problematic welds. The production of the top plate of the water tank also requires strict size control. The installation of the top plate should be closely matched with the side plate without gaps. Suitable positions should be reserved in advance for the inlet and outlet of the water tank. The installation of inlet and outlet pipelines should ensure the sealing of the connection.

Proper anti-corrosion treatment should be carried out at the pipeline connection to extend its service life. Reinforcement

bars need to be installed inside the water tank to enhance its structural strength. The spacing and specifications of reinforcing bars are determined based on the size of the water tank. After installation, conduct an overall sealing test on

the water tank. Fill the water tank with water and check for any leakage. If there are leakage marks, targeted repairs

should be carried out. After repair, test again until there is no leakage before passing. The outer surface of the water tank

should be sprayed with anti-corrosion coating. Choose anti-corrosion coatings with good weather resistance to ensure

effectiveness. Control the distance and pressure of the spray gun during spraying.

Ensure that the coating thickness is uniform and meets the specified standards. Check the surface for defects after the

coating dries. Polish and repaint the defective areas. Suitable support structures should be installed at the bottom of the

water tank. There are strict requirements for the material and spacing of the supporting structure. The supporting structure should be able to withstand the weight of the water tank when it is fully loaded. Clean the overall appearance of

the produced water tank. Check if there are any scratches or dents on the surface of the water tank. Label the water tank

with product identification indicating specifications and parameters. Conduct sampling performance testing on finished

water tanks. We will only allow Dafeng to sell products after all performance indicators are qualified.