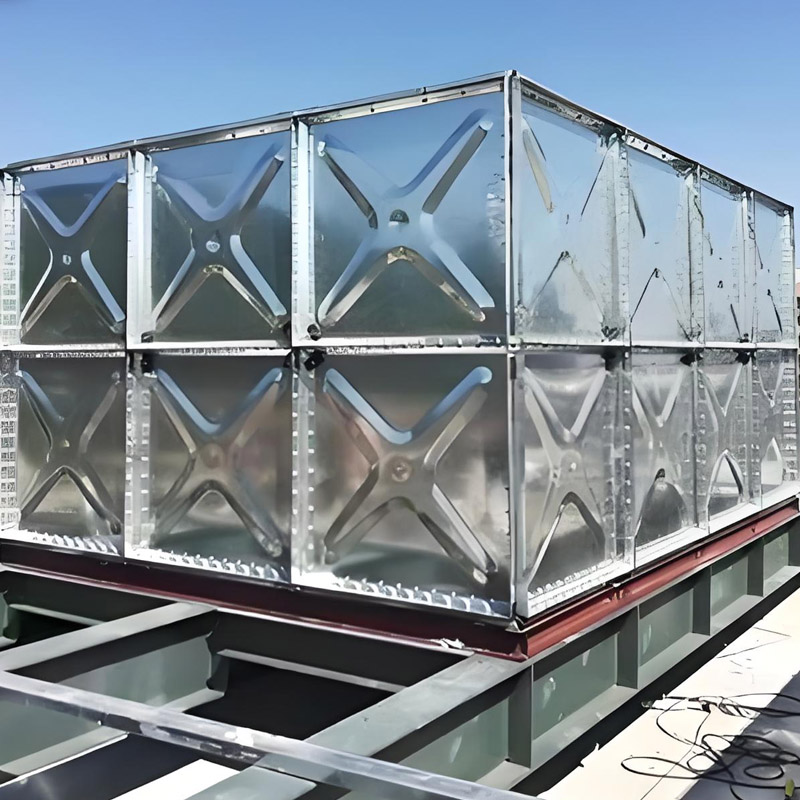

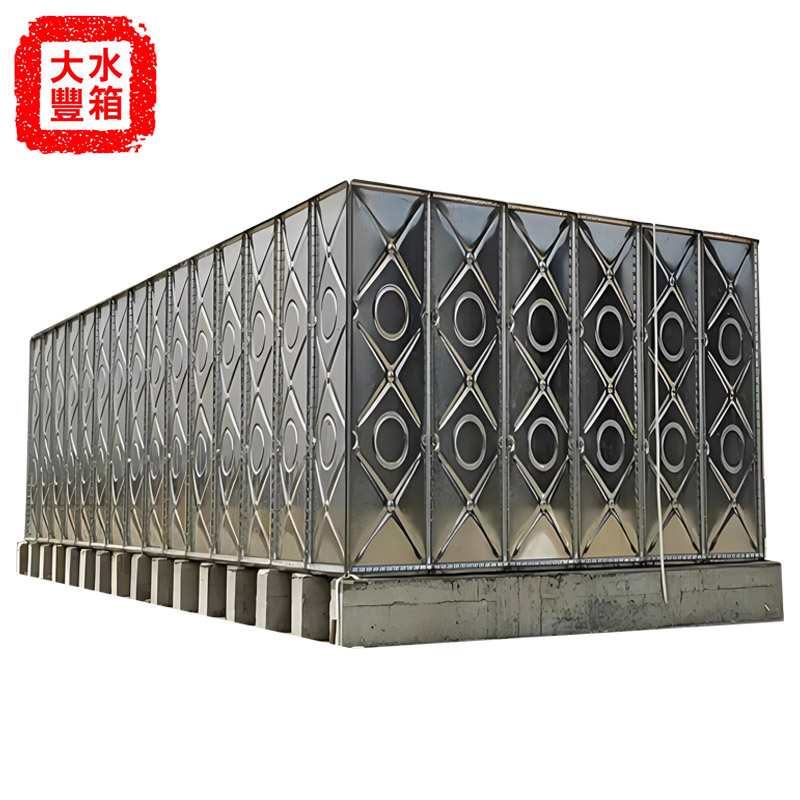

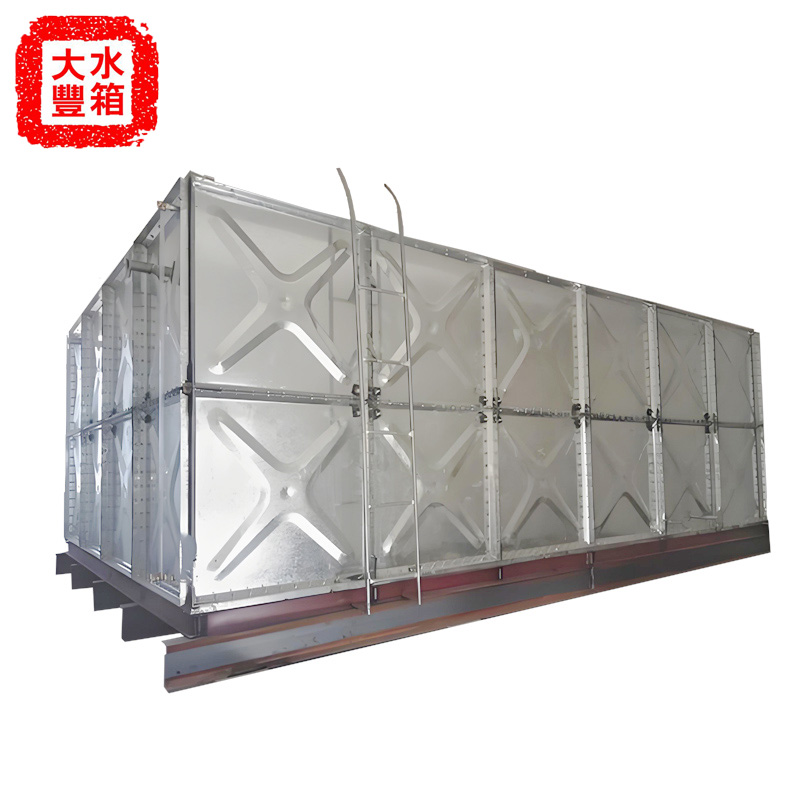

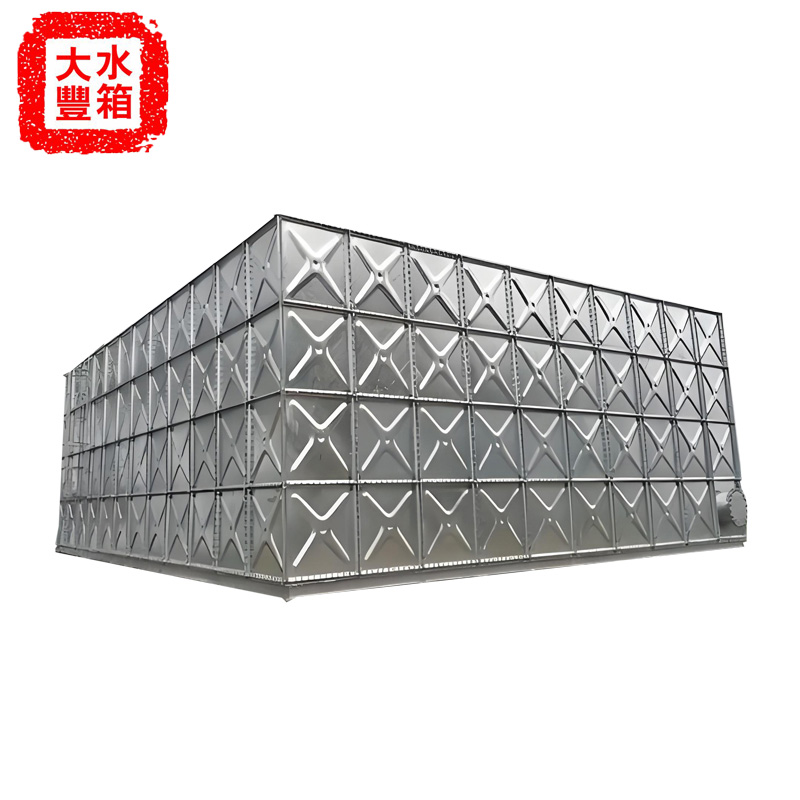

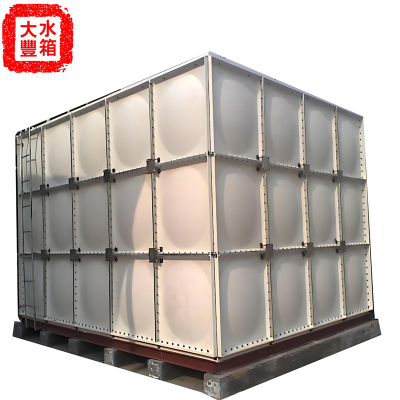

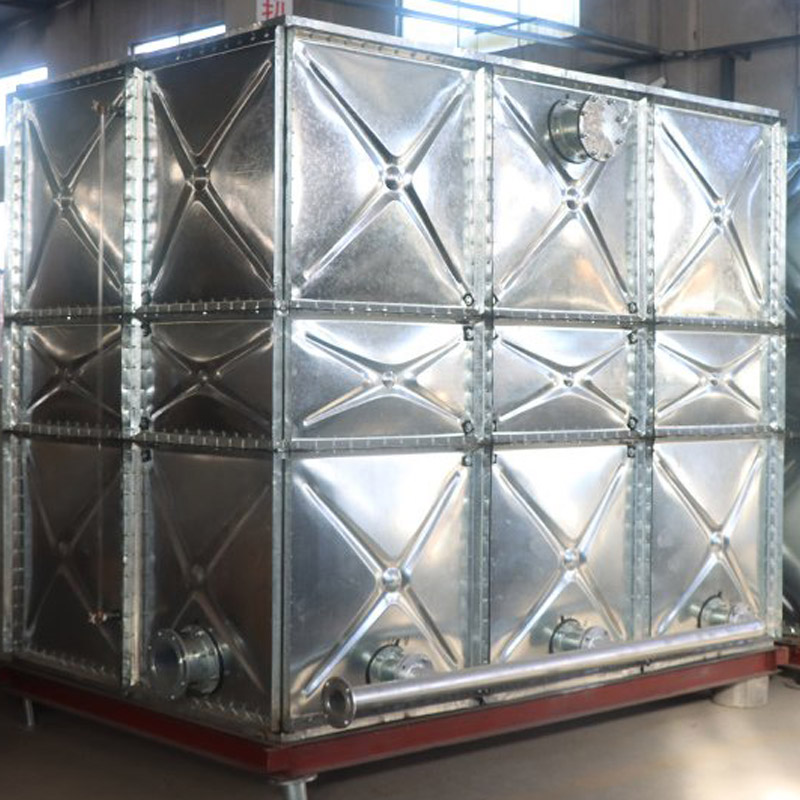

Hot Dip Galvanized Water Storage Tank

ShanDezhou Dafeng Glass Products Co., Ltd. has a high-quality R&D team and advanced production equipment, which can customize various specifications of water tank products according to customer needs. The galvanized water tank produced by the company adopts advanced hot-dip galvanizing technology, which forms a dense zinc layer on the surface of the water tank and has good corrosion resistance. We are directly supplied by the original manufacturer. Welcome new and old customers to consult and purchase!

The production process of hot-dip galvanized sheet mainly includes: original sheet preparation → pre plating treatment → hot-dip coating → post plating treatment → finished product inspection, etc. However, some non professional manufacturers in daily life may directly affect the speed and quality of galvanizing due to improper operation and other factors in the actual production process.

Common factors include:

(1) Incomplete handling. There is an oxide film on the surface of the workpiece, which affects the normal deposition of zinc.

(2) Poor conductivity. The current is consumed on the wire, and the current distributed to the surface of the workpiece is too small.

(3) The workpiece has a high carbon content. High carbon steel, cast iron parts, etc. will reduce the hydrogen evolution potential, accelerate the hydrogen evolution on the surface of the workpiece, and reduce the current efficiency.

(4) The workpiece is tied too tightly. During galvanizing, the workpiece is partially shielded, resulting in a thin coating.

(5) The temperature of the plating solution is too low. When the temperature of the plating solution is low, the current density delivered decreases accordingly, and the deposition rate of the coating is inevitably reduced.

(6) The sodium hydroxide content in the plating solution is relatively high. When the content of sodium hydroxide is too high, the current efficiency decreases accordingly.

(7) The additive content in the plating solution is low. Low additive content can affect dispersion ability and make the

coating appear too thin locally.

(8) The workpiece suspension method is improper and the distance between it and the zinc anode is too large. The

position should be adjusted.

(9) The workpiece is corroded. Lowering the hydrogen evolution potential reduces the current efficiency of accelerating hydrogen evolution on the surface of the workpiece, thereby affecting the deposition rate of zinc. An appropriate amount of corrosion inhibitor should be added to the acid pickling solution. If the oxide scale is too thick in some areas, it should be removed by mechanical method first. During the acid pickling process, more inspections should be carried out.

(10) Anodic passivation. The reduction of effective area affects the normal distribution of current.

(11) The sodium hydroxide content is low. If the content of sodium hydroxide is low, the current density cannot be increased and the anode is passivated.

(12) The estimated area of the plated part is insufficient, and the current density delivered during plating appears to be too low. A thick and dense pure zinc layer covers the surface of steel fasteners, which can prevent the steel substrate from coming into contact with any corrosive solution and protect the steel fastener substrate from corrosion. The quality of its protective performance is closely related to the thickness of the coating, and Dafeng hot-dip galvanized water tank ensures the thickness of the coating. Friendly reminder, everyone must choose a legitimate enterprise to avoid rusting caused by the thin zinc layer on the water tank.