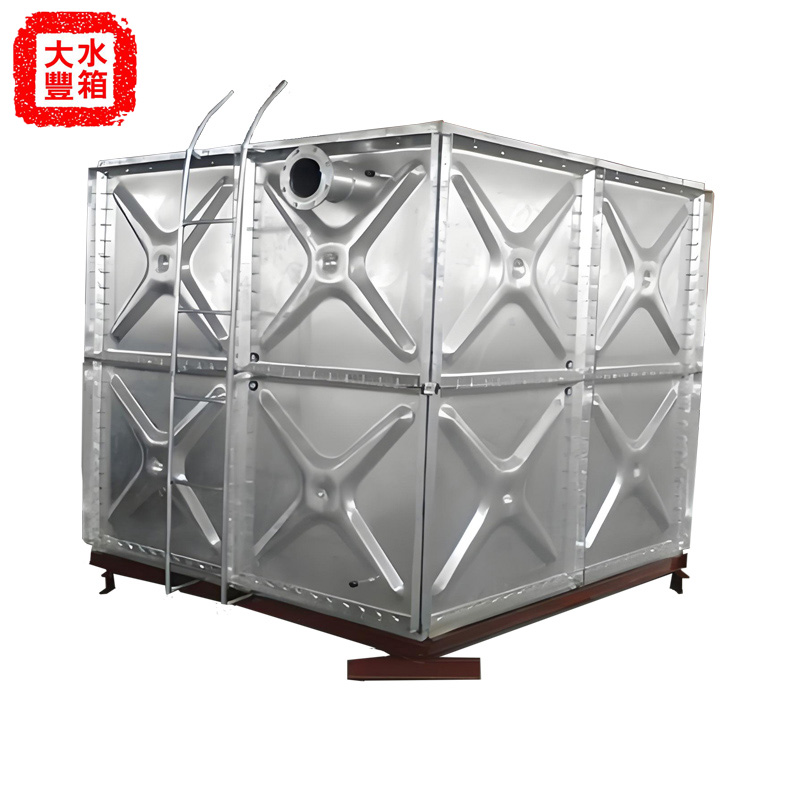

Square Galvanized Water Tank

ShanDezhou Dafeng Glass Products Co., Ltd. has a high-quality R&D team and advanced production equipment, which can customize various specifications of water tank products according to customer needs. The galvanized water tank produced by the company adopts advanced hot-dip galvanizing technology, which forms a dense zinc layer on the surface of the water tank and has good corrosion resistance.

Precautions for galvanized steel plate water tank:

The use and maintenance of galvanized steel plate water tanks require attention to multiple details to ensure safety and

durability. The material selection directly affects the service life of the water tank, and attention should be paid to the

thickness of the steel plate and the galvanizing process when selecting. It is recommended to choose steel plates with a

thickness of no less than 2 millimeters for ordinary environments, and thicker plates are needed for coastal or high

humidity areas. The thickness of the galvanized layer should reach a standard of not less than 275 grams per square

meter. Magnetic adsorption can be used on site to test whether the galvanized layer is uniform. Excessive adsorption force may indicate that the zinc layer is too thin. Poor quality galvanized layers may develop rust spots within six months, and the manufacturer is required to provide a material inspection report when purchasing.

The installation process requires professional personnel to operate. The foundation platform must be poured with

concrete and leveled, with a horizontal error controlled within 5 millimeters. An uneven foundation can cause uneven

stress at the bottom of the water tank. Use carbon dioxide protection welding during welding, clean up welding slag in a

timely manner after welding, and apply zinc layer repair paint. A water tank leakage accident occurred in a certain residential area due to rusting at the weld seam two years later caused by workers' failure to clean the welding slag. The

sealing strip should be made of aging resistant EPDM material, and the joint should be filled with food grade sealing glue. After installation, it should be filled with water and left to stand for 48 hours to observe leakage.

Daily use requires controlling the water level within the calibration range. However, an operator at a certain factory forgot

to close the inlet valve, resulting in nighttime overflow and water seeping into the distribution box, causing a short circuit. Check the box for bulges or deformations every week, with a focus on inspecting the welds and edges. The water quality remains neutral, with a pH value between 6-8. Acidic water will accelerate the corrosion of the galvanized layer. The cleaning cycle should not exceed six months, use a soft bristled brush with neutral detergent, and avoid using steel wire balls or strong acid cleaners. When the temperature drops below zero in winter, draining the stored water or installing a heat tracing strip caused a water tank to freeze and crack in a breeding farm in the north, resulting in losses of tens of thousands of yuan.