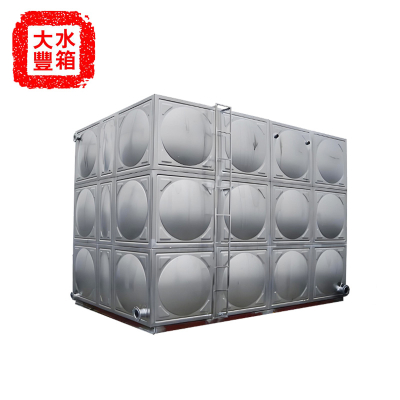

Stainless Steel Bolted Water Tank

The surface of stainless steel material is smooth and the appearance is clean and tidy. It can be coordinated with various architectural styles. It is not only a water storage device, but also a decorative element. Not easy to scale and not prone to bacterial growth. Daily maintenance only requires regular cleaning, with low maintenance costs.

Product Details of Stainless Steel Bolte Water TankTank Body:

It is made of high-quality stainless steel plates, and commonly used models include SUS304, SUS316L, etc. SUS304 has good corrosion resistance and comprehensive performance, and is suitable for the storage of general water quality. The thickness of the plates is reasonably selected according to the capacity and height of the water tank to ensure the strength of the water tank.It includes inlet and outlet pipes, overflow pipes, sewage pipes, manholes, ladders, etc. The inlet and outlet pipes are equipped with different pipe diameters according to the purpose of the water tank and the flow rate requirements to ensure smooth water flow. The overflow pipe can prevent the water in the tank from overflowing when it is full. The sewage pipe is convenient for the regular cleaning and sewage discharge of the water tank. The manhole is convenient for personnel to enter the interior of the water tank for maintenance and inspection. The ladder is installed on the side of the water tank for personnel to go up and down.

Capacity:

Various specifications can be customized, which can meet the needs of different scenarios, ranging from small domestic water tanks of several hundred liters to large industrial water tanks of several thousand cubic meters.Working Pressure: It can withstand a certain water pressure. The specific value is determined according to the design and structure of the water tank. Generally, it can meet the pressure requirements of conventional water supply systems to ensure safe and stable operation.

Forming Processing:

Through processes such as stamping and bending, the cut plates are processed into various components required for the water tank to ensure that the shape and size of the components meet the design requirements.Screw Connection and Assembly: Screw holes are opened at the edges of the components, and food-grade 304 stainless steel screws are used for connection. When installing, a non-toxic rubber sealing gasket is placed at the connection to ensure the sealing performance and overall strength of the water tank, and it is also convenient for disassembly and maintenance.