Enamel Insulated Water Tank

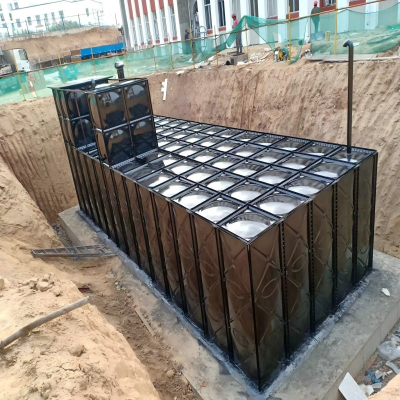

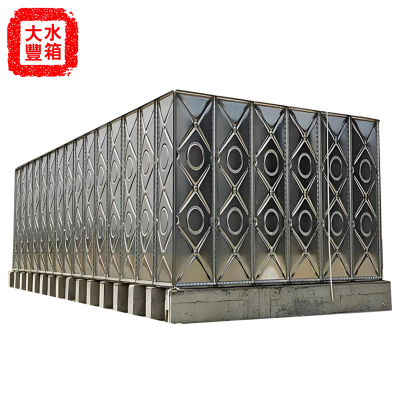

Enamel insulated water tank is a water tank with insulation effect inside, with an inner layer of 304 steel plate, an outer layer of 201 steel plate, and a core layer of polyurethane steel plate. Through optimized combination, the inner and outer layers achieve insulation effect together. And our Dafeng enamel insulated water tank has corrosion resistance, high temperature resistance, excellent sealing performance, and a smooth and flat enamel layer surface. Welcome new and old customers to consult and purchase!

Enamel insulated water tank:

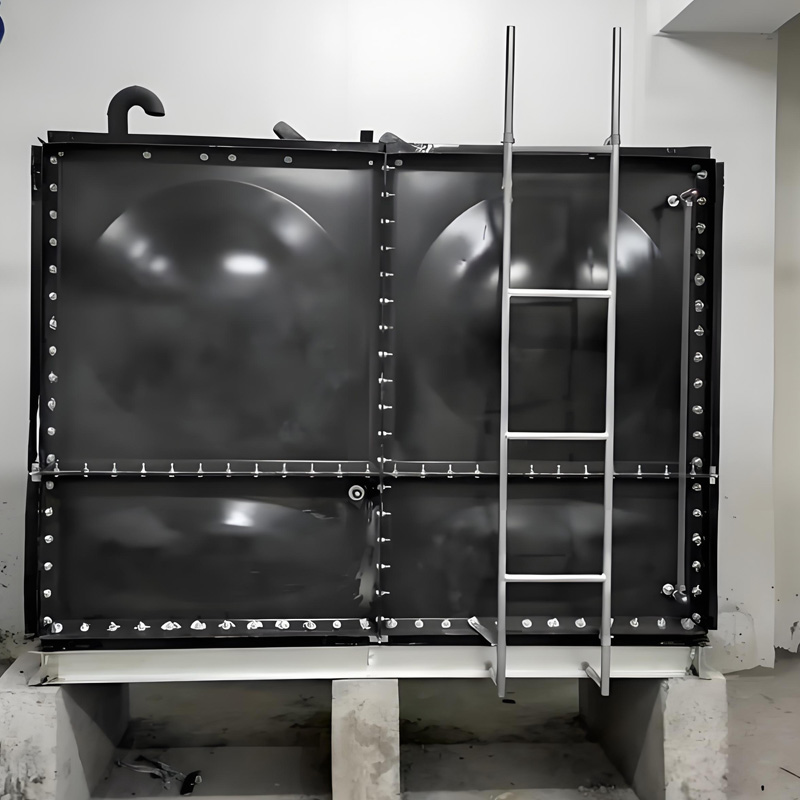

Enamel water tank is a water tank with insulation effect inside. Its inner layer is made of 304 steel plate, outer layer is made of 201 steel plate, and core layer is made of polyurethane steel plate. The three are combined from inside to outside, and through optimized combination, the inner and outer layers achieve insulation effect together. Due to the use of polyurethane insulation material (polyurethane is currently a high-performance insulation material internationally, and hard polyurethane has excellent properties such as light weight, low thermal conductivity, good heat resistance, aging resistance, easy adhesion with other substrates, non combustion, and no droplet formation), the enamel water tank uses polyurethane as its core layer, and the insulation medium for the core layer can be 50mm or 80mm polyurethane foam, polymer, PEF and other materials, so that the inner and outer layers can achieve the best insulation effect together.

The anti-corrosion effect of enamel water tank:

The enamel water tank produced by Dafeng has better anti-corrosion effect. Although the inner liner of the enamel water tank is made of stainless steel material, it may still corrode when there is a high chlorine content in the water. The activity of enamel is very weak, and it undergoes extreme chemical reactions, just like the bowl we use for eating. If it is a stainless steel bowl, rust will appear after being stored for a long time or used for a period of time, so the enamel inner liner water tank has an advantage in anti-corrosion performance. The enamel manufacturing process is relatively mature, and the qualification rate of producing enamel water heater liner products is relatively high. The enamel manufacturing industry in our country has a history of over a hundred years. It is made according to the enamel process and has relatively stable performance.

The use of enamel water tanks in water heater production is increasing in China. Due to its superior anti-corrosion performance, enamel inner liners are replacing them as the mainstay of water heater inner liners. Silicon in enamel water tanks not only reduces the toughness and ductility of steel, making it difficult to carry out deep drawing processing, but also has a negative impact on the adhesion performance between steel and enamel. This is because when steel is heated, silicon forms silicon dioxide on the surface of the steel, weakening the interfacial chemical reaction and hindering the wetting and penetration of iron by enamel, thereby reducing the adhesion strength of enamel. In addition, silicon can also reduce the pickling efficiency of steel. Due to the accelerated absorption of hydrogen by steel plates during silicon pickling, the probability of "phosphorus explosion" increases.