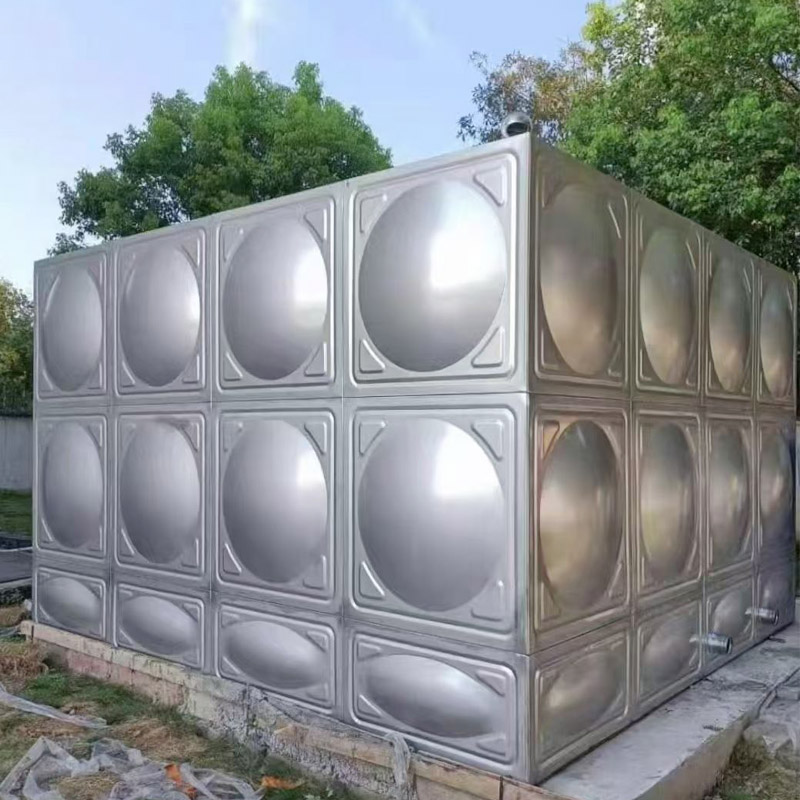

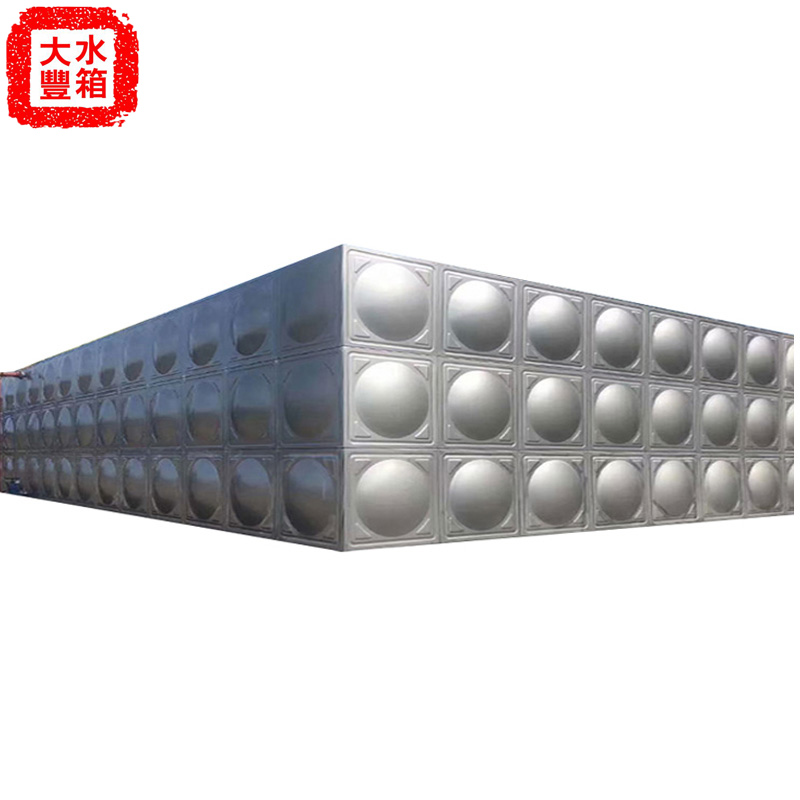

304 Square Water Tank

Square water tanks are often installed in basements or rooftops, commonly known as stainless steel square water tanks or stainless steel water tanks, and are composed of multiple stainless steel water tank stamping plates. The stainless steel square water tank is safe, hygienic, and durable. The entire system is enclosed, and the surface of the stainless steel material is smooth, which is not easy to attach algae and wash away sediment in the water.

Stainless steel water tank execution standard

一、 Material standards:

1.The main structure of the water tank should be made of 304 stainless steel plate, and the thickness of the plate should be determined according to the specifications and pressure bearing capacity of the water tank, but the minimum thickness should not be less than 0.4mm.

2. The internal accessories of the water tank, such as rods, supports, and reinforcing ribs, should be made of 304 stainless steel material that is the same as the main structure.

3. The sealing components of the water tank should be made of high-quality rubber or polytetrafluoroethylene materials

that are resistant to high temperatures and corrosion.

4. The fasteners of the water tank should use stainless steel bolts and nuts, and be treated with anti-corrosion according

to national standards.

二、Structural Design Standards

1. The structural design of the water tank should comply with relevant national standards and meet usage requirements

to ensure structural stability, safety, and reliability.

2. The structural design of the water tank should be reasonable, easy to clean and maintain, while considering drainage

and ventilation to prevent corrosion and pollution caused by accumulated water and moisture.

3. The structural design of the water tank should reasonably distribute support and reinforcement bars to ensure that the

water tank will not deform or be damaged during use.

4. The position of the inlet and outlet pipes of the water tank should be designed reasonably to facilitate connection and

operation, while considering the requirements of water pressure and flow rate.

三、Hygiene standards :

1. Stainless steel water tanks should comply with national hygiene standards to ensure safe and hygienic water quality.

2. The interior of the water tank should be smooth, free of dead corners, welding slag and other protrusions to prevent

scaling and bacterial growth.

3. The internal accessories of the water tank should be easy to disassemble and clean, facilitating regular maintenance

and cleaning.

4. The water tank should be regularly cleaned and disinfected to maintain the cleanliness and hygiene of the water quality.

四、 Welding process standards:

1. Stainless steel water tanks should be welded using argon arc welding or plasma welding processes to ensure welding

quality and service life.

2. Welding personnel should undergo professional training and obtain corresponding qualification certificates to ensure

that the welding quality meets the requirements.

3.Before welding, the stainless steel plate should be cleaned and polished to remove surface dirt and oxide layers to ensure welding quality.

4.During the welding process, qualified welding materials and process parameters should be used to ensure the quality

and aesthetics of the weld seam.

5. After welding is completed, non-destructive testing should be carried out on the weld seam to ensure that there are no

defects such as cracks or pores.

6.For large and medium-sized stainless steel water tanks, overall heat treatment should be carried out to eliminate welding stress, prevent water tank deformation and cracking.

7.Before putting the water tank into use, a comprehensive inspection of all welds should be conducted to ensure welding

quality and safe use.