Stainless Steel Water Tank

Technical necessities for stainless metal water tanks:

(1) The water tank is made of SUS304 or greater grade stainless metal plate, stamped and formed,and must comply with the countrywide OCr18Ni19 hygiene inspection standard. It need to no longer rust,grow moss, leak water, completely keep cleanliness and hygiene, and be secure and stable.

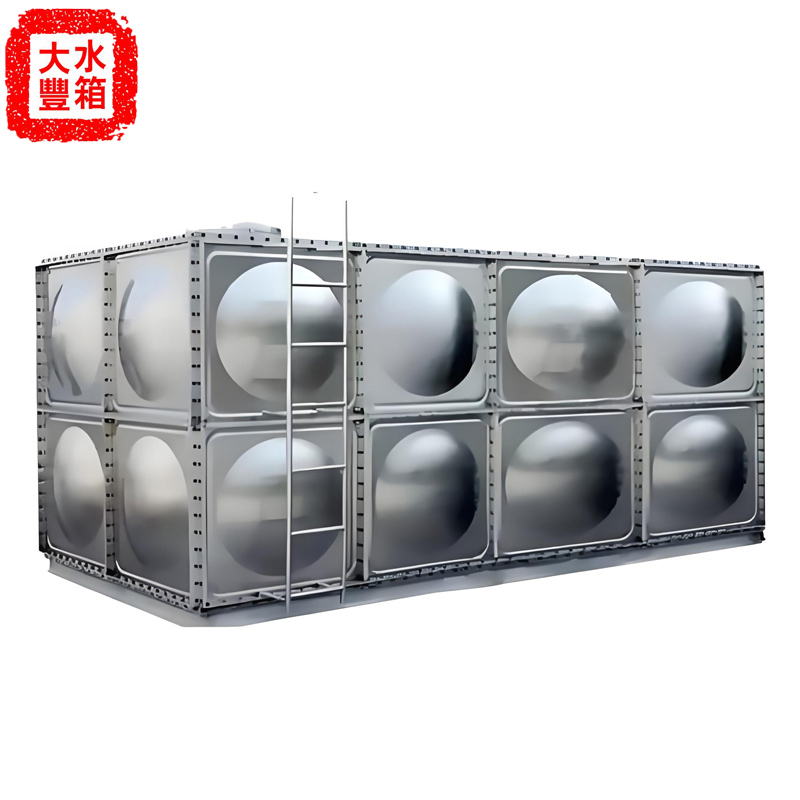

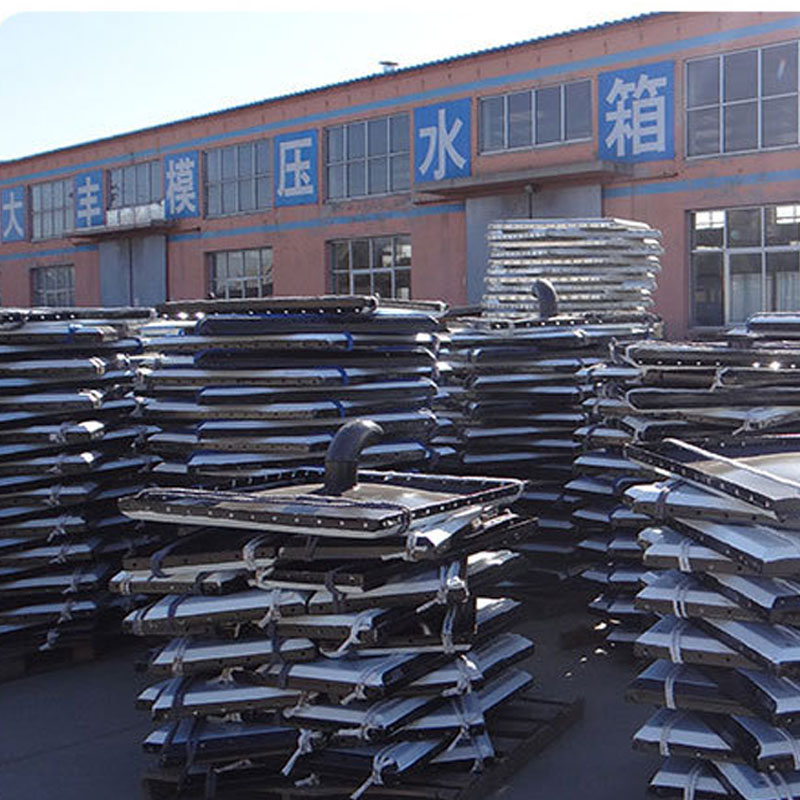

(2) The modular stainless metal water tank is composed of three most important fashionable modules, specifically1000 * 1000, one thousand * 500, and five hundred * five hundred trendy blocks. According to exclusive 3-dimensional format parameters, modules of one of a kind thicknesses are used for welding and meeting in the manufacturing unit or on site. Argon arc welding is used on site, and the weld floor is dealt with with acid pickling and passivation to make certain sturdiness and corrosion resistance of the weld. The chassis needs to use hot-dip galvanized Q235-A carbon metal channel steel.

(3) Small warmth change station water tank: inlet (DN50, 1), outlet (DN50, 2), overflow port (DN65,1), sewage outlet (DN50, 1), vent gap (DN32, 1), manhole (φ 700, 1), two liquid stage gaugeinterfaces, and interior and exterior ladders. The interface measurement and function are quickly determined, and the interface is flange related with corresponding anti flange seals and fasteners.

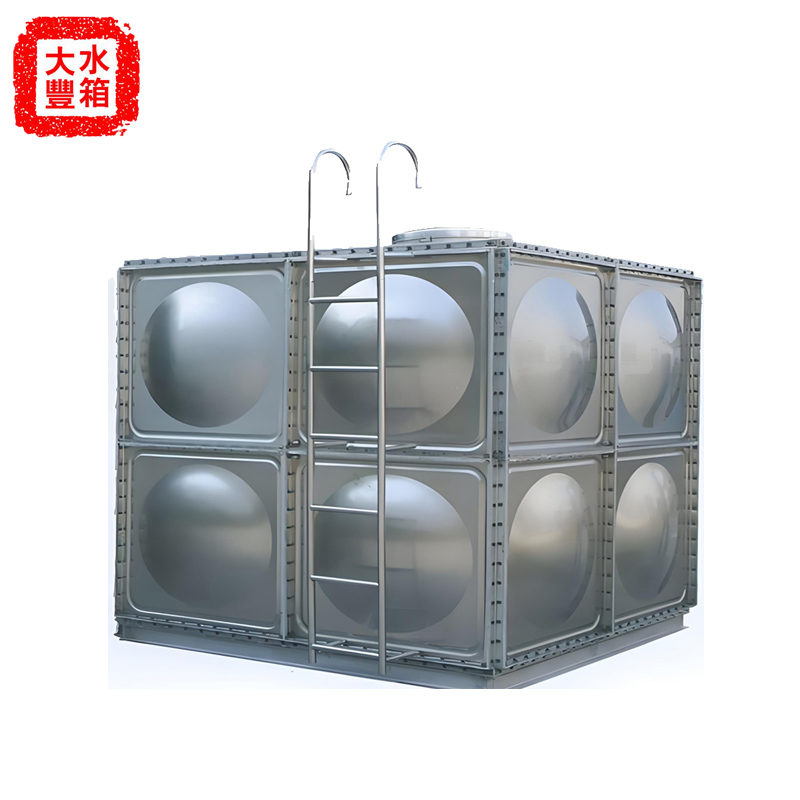

(4) After the welding of the water tank is completed, all fasteners ought to no longer be loose, and there must be no welding or element leakage in any connecting parts.

(5) The weld seam of the water tank have to be full, and the outer welding floor of the water tank should be smooth, beautiful, barring slag inclusion, weld bead, porosity, or cracks. The welding interface must no longer have concave cracks, separation, or hand cutting. The weld seam of the water tank liner wants to be polished.

(6) The flat backside plate of the water tank ought to be saved flat.

(7) The pinnacle of the water tank and the manhole have to be thoroughly welded, and the exceptional necessities are the identical as above.

(8) The connection ports of the water tank need to be nicely welded and saved as vertical as possible, with a minimal inclination of 1 °.

(9) The insulation layer is firmly mixed with the floor of the water tank, and the look is smooth. The outer ornamental shell is made of stainless metal plate, made of SUS201 material, with a thickness of 0.5mm, and the floor have to no longer be uneven, scratched or rusted. The allowable tolerance for exterior dimensions have to meet the necessities of the allowable tolerance desk for dimensions.

(10) The water tank must be crammed with water besides any leakage or seepage, and there ought to be no apparent deformation. It have to be examined in accordance to the applicable water take a look at phrases for metal welded atmospheric strain vessels.

(11) The water tank need to be stored vertical when erected, and the verticality ought to meet the requirements of the allowable tolerance desk for dimensions.