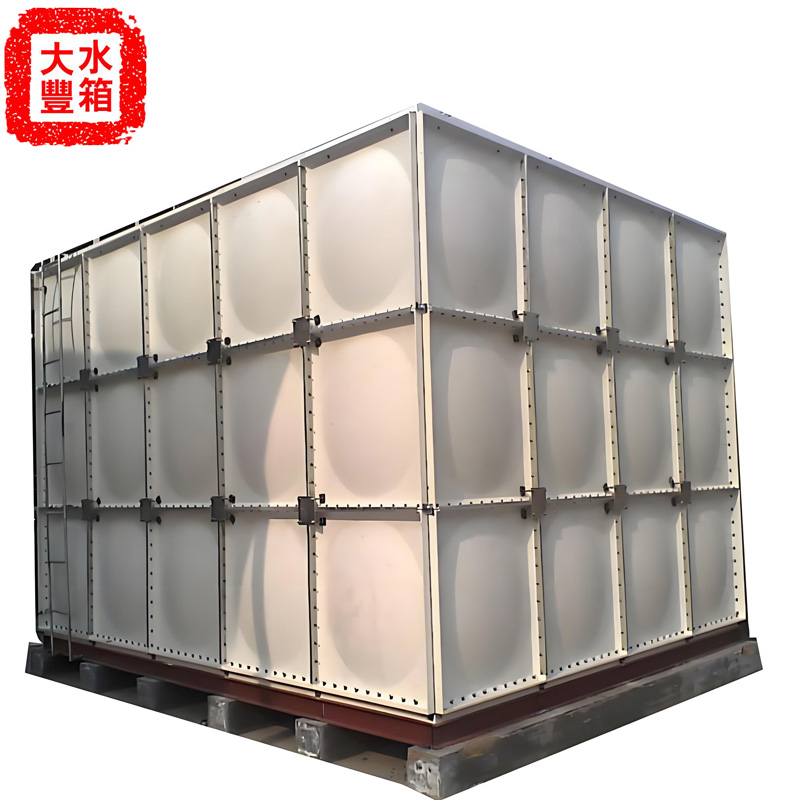

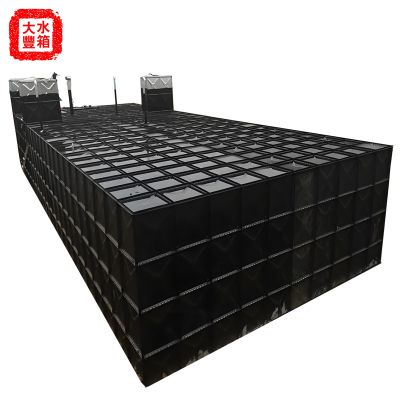

Fiberglass Compression Mold Water Tank

SMC insulated water tank is a new type of water tank currently used. Assembled from high-quality SMC water tank panels as a whole. Our high yield SMC insulated water tank has a beautiful appearance, corrosion resistance, light weight, long service life, compact structure, and occupies a very small area!

Fiberglass molded water tank is a modular water storage equipment based on glass fiber reinforced plastic, which has the characteristics of corrosion resistance, lightweight, and flexible customization. It is mainly used in fire water supply, agricultural irrigation, industrial water storage, and so on.

The manufacturing process of fiberglass compression molded water tank:

The prefabricated SMC fiberglass water tank used by Dafeng Water Tank Factory is made of resin sheets. The quality of this raw material has a decisive impact on the laminating process of SMC fiberglass water tank panels. Therefore, extra caution should be taken when selecting and storing resins to ensure their superior quality. The process of making SMC water tanks requires high precision, from material preparation to molding, every step is crucial.

The press for SMC fiberglass water tank panels has a maximum pressure of up to 2000 tons, which ensures the density of the molded panels and guarantees high-quality product output. Before laminating, a series of preparation work is required, including quality inspection of SMC, cutting out the required shape, and thorough cleaning of the mold. Subsequently, the press enters the preparation state, waiting for the material block to enter the mold cavity. Once the material block is in place, the press quickly descends to ensure precise alignment between the upper and lower molds. At this point, the required molding pressure needs to be slowly and steadily applied, and the molding process can only be completed after sufficient curing time. Reasonable selection of various process parameters and operating conditions of the press is crucial throughout the entire molding process.