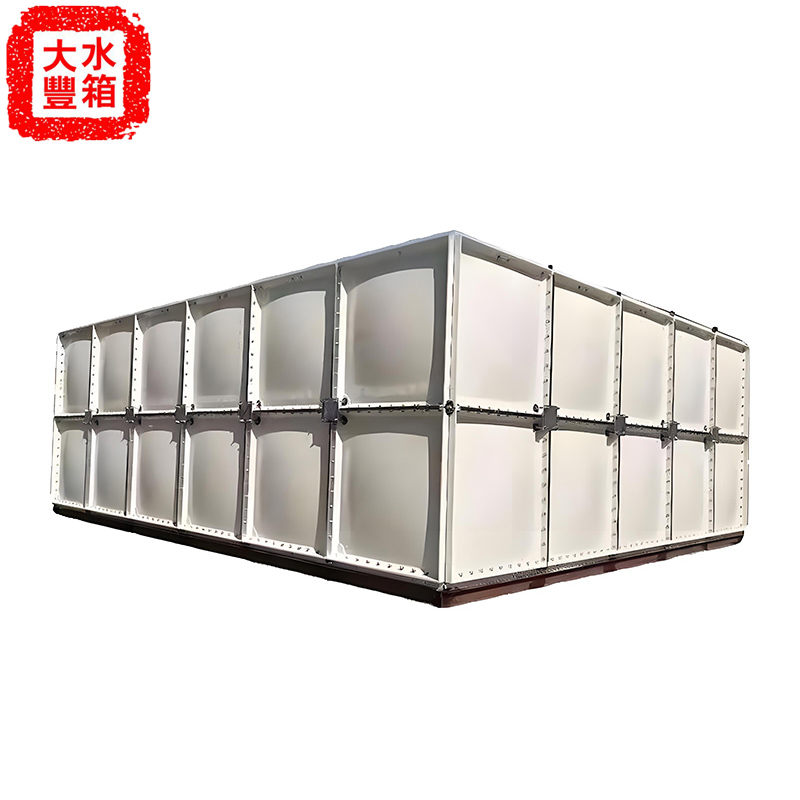

SMC Civil Air Defense Water Tank

SMC insulated water tank is a new type of water tank currently used. Assembled from high-quality SMC water tank panels as a whole. Our high yield SMC insulated water tank has a beautiful appearance, corrosion resistance, light weight, long service life, compact structure, and occupies a very small area.

Construction and installation plan for SMC civil air defense water tank:

1、 First, level the surface of the cement foundation so that it is on the same plane, with an error not exceeding ± 0.5cm.

2、 Welded channel steel: The channel steel is welded according to the size of the water tank, and its size matches the size

of the water tank bottom plate After welding is complete, measure the dimensions diagonally with an error of ± 0.5cm,

and all welds must be connected evenly and arranged uniformly.

3、 Install the bottom plate: Arrange and connect the bottom plate of the water tank according to the printed number

and instructions on the single board of the water tank, and at the same time Add a sealing strip between two veneers and

connect them with bolts of size 10. Make the bottom plate seal firmly, screw When applying force to bolts, it is necessary

to apply force evenly at once, with each bolt applied 3-4 times. Excessive force should not be applied at once The cracking

phenomenon is caused by uneven force.

4、 Connect the bottom plate and channel steel with fixed angle iron to make the water tank body more firmly fixed on

the channel steel foundation.

5、 Install each state: Based on the printed numbers and instructions on the water tank panel, identify the state numbers

for each layer of the water tank body, and And separate them in advance, assemble the body with bolts. Stand the water

tank board upright and align it to form a bond with the bottom bond 90 degree angle, with encrypted sealing tape,

tighten bolts.

6、 Install internal reinforcement: According to the size of the water tank, find the correct number and length of internal

reinforcement. Measure with a tension plate Measure the tightening position of the tension bar, draw a mark, drill holes,

align the wire, tighten, and make the tension Smooth reinforcement and water tank The box maintains balance. If there is

a significant error between the box and the tension bar, the degree of bolt tightening can be adjusted Adjust the error

size until the error is minimized Stop.

7、 Installation of cover plate: Finally, install the top cover plate of the water tank and tighten the bolts evenly without

applying too much force or force Small. After adjusting all the fasteners of the water tank, open the holes according to the drawing position, Open all the water pipes, go up Good flange for valve docking.

8、 After the installation of all water tanks, a unified inspection, adjustment, and water test should be conducted to ensure that there is no leakage, which is considered qualified.