Enamel Fire Water Tank

The advantages of enamel fire water tank:

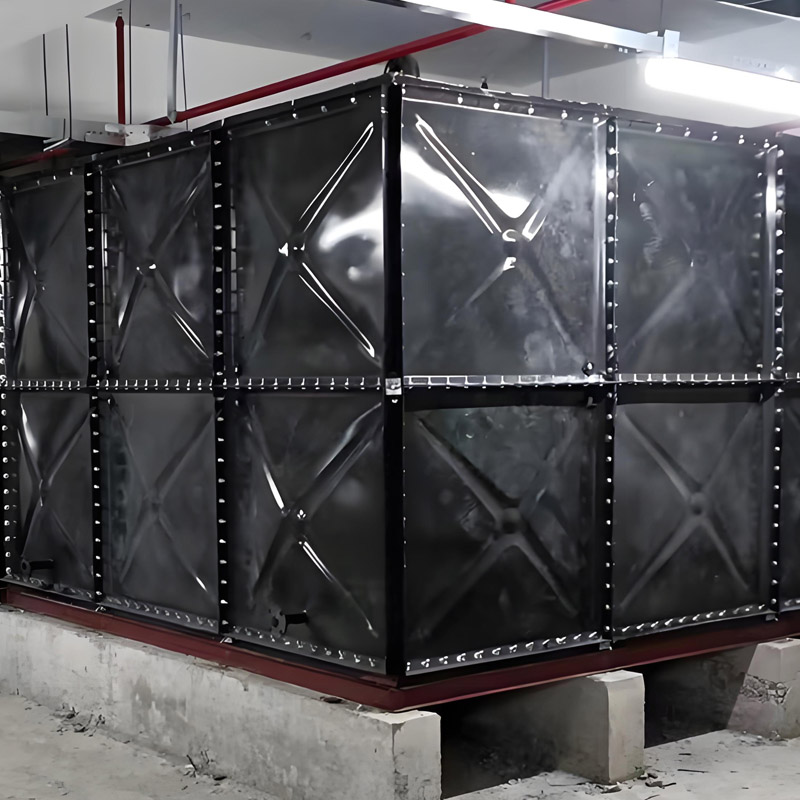

The advantage of enamel layer is that it can resist acid, alkali, wear, impact, cold and hot changes, and has good adhesion, which can provide good protection for the inner liner. Enamel is a composite glassy material, which is essentially a silicide. During production, the enamel is first applied to the metal surface, then melted by heating, and cooled to evenly solidify the enamel on the surface of the metal material and tightly bond with it, producing a dense enamel layer that isolates the carbon steel substrate from water. Its essence is to prevent the contact between the electrolyte solution and the metal material, thereby preventing electrochemical corrosion of the water heater liner. The enamel water tank is designed with a concave curve in the middle of the plate, which increases the

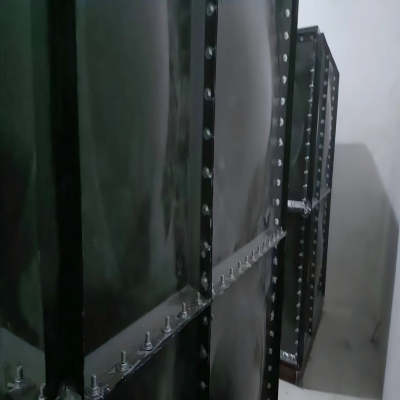

pressure bearing capacity of the water tank. At the same time, there are 45 ° and 90 ° flanges around the plate, which are connected at the corners during assembly, making it more flexible and adaptable.

Enamel water tank selects parts and materials based on water quality:

1. Drinking water: If it is drinking water, there is no doubt that the requirements for water quality are high. Therefore, only those made of metal materials need to be prioritized for better food safety and value.

2. Non drinking water: If it is non drinking water, the requirements for water quality are not so high. Hot dip galvanizing or cold dip galvanizing can be used, but due to the easy rusting of cold dip galvanized parts, hot dip galvanizing materials are more commonly used in most cases.

Attention should be paid to the installation of enamel steel plate water tank:

1. When installing the enamel water tank, it is necessary to handle it gently to avoid excessive force that may knock off the porcelain in the tank.

2. Attention should be paid to the installation of water tanks made of other materials, including enamel steel plates. Many users who have purchased water tanks believe that enamel water tanks do not have such high technical difficulty. As long as there is a molding machine and a template, they can be made. However, this is not the case. There will be many problems in the selection of materials, feeding of plates, thickness of clamping plates, calculation of water pressure,

design of plate thickness, pressing plate, enamel and other processes. These are all technical issues, and any problem in any link will affect the quality of the plate.

Precautions for installation of enamel water tank:

The diameter and position of the inlet pipe, outlet pipe, and overflow pipe of the water tank are determined by the design; There should be no less than 700mm channels around the water tank, and no less than 600mm channels at the bottom and top of the tank. During installation, the connection gaps around the bottom of the tank and before the standard block at the bottom of the tank should be located on the support. Internally reinforced with stainless steel tension bars, the plates are sealed with rubber strips and fastened with bolts to increase their strength. Water filling test: After the water tank is installed, close the outlet and discharge pipes, open the inlet pipe, and check while draining water until it is full. If there is no water leakage after 2-3 hours, it is considered qualified.