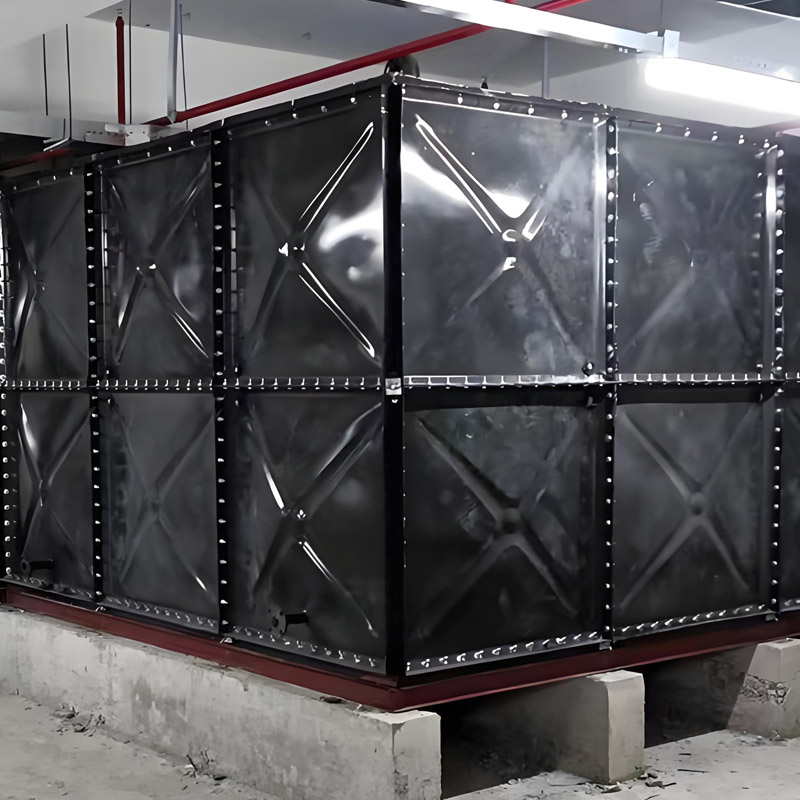

Prefabricated Enamel Steel Plate Water Tank

Overview of prefabricated enamel steel plate water tank:

Our company's prefabricated enamel steel plate water tank adopts advanced technology and selects high-quality materials to ensure clean water quality. And it is corrosion-resistant, easy to clean, and has a longer service life than ordinary water tanks. It is now easy to assemble, flexible, not easily deformed, and has high impact resistance. This product has achieved good results after long-term use, and our company has now produced it in large quantities. As the product develops towards universality, standardization, and serialization, the quality of the product has been reliably guaranteed. Enamel steel plate water tanks have a wide range of applications, not only suitable for new construction projects, but also providing convenient conditions for the replacement of water tanks in old buildings. The water tank can store both cold and hot water, with acid and alkali resistance, and no leakage The advantages of no leakage, no deformation, and no corrosion, if needed, please feel free to contact us at Dafeng.

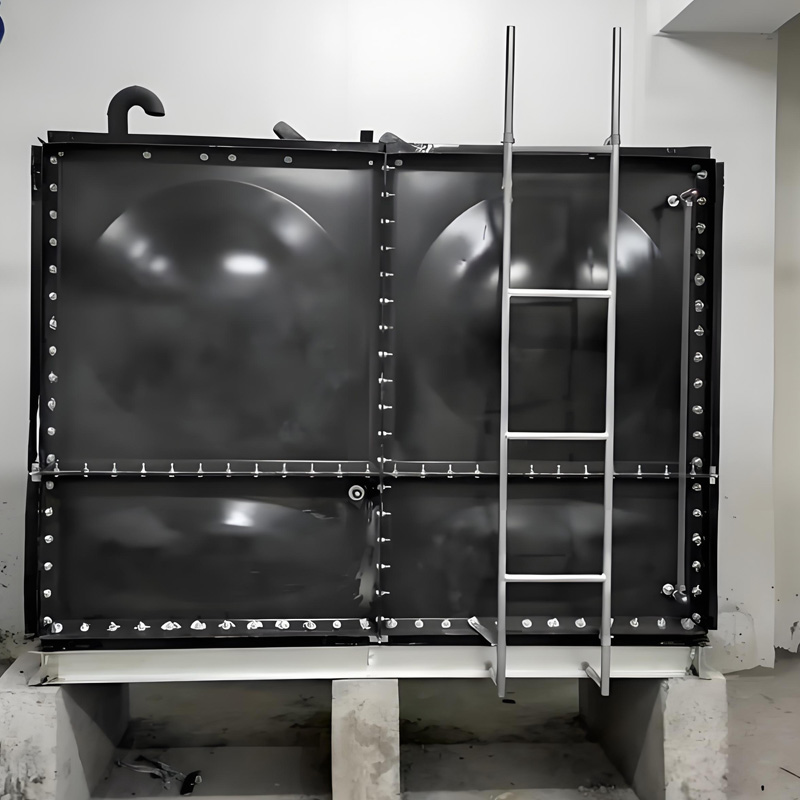

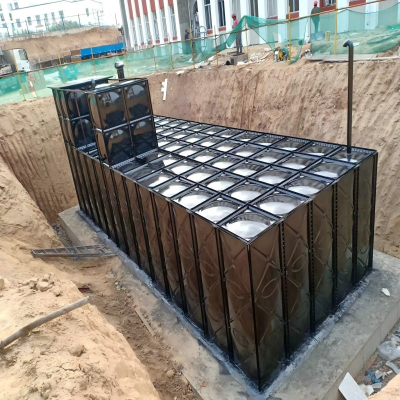

Our Dafeng prefabricated enamel steel plate water tank adopts advanced technology, selects high-quality materials, and undergoes high-temperature sintering of enamel to form a dense glaze layer on the surface of the water tank. It penetrates into the steel plate interface ions before mixing to form a diffusion layer with a thickness of about 200-300 microns, which increases the adhesion strength of the enamel surface. The enamel surface is smooth, easy to clean, and corrosion-resistant. Moreover, it is easy for workers to assemble, not easily deformed, and has high impact resistance. Through long-term and extensive use, it has a very good effect. Enamel steel plate water tanks can hold hot water below 60 ℃ and can be used for burial, but cannot hold drinking water. Their service life is longer than other water tanks.

The use places of enamel steel plate water tanks:

regulation of building water supply, fire water tanks, storage water tanks, expansion and condensation water tanks of heating systems, temporary storage water tanks for construction, road construction, geological exploration, national defense engineering, service areas, hotels, hospitals, gas stations, bathing centers, water equipment treatment companies. Hotels, buildings, restaurants, research and teaching buildings, offices, offices, villas, gardens, residential communities, and other secondary water supply facilities for hygiene, food processing, and other purposes. For the convenience of renovating old building water storage tanks, when the water tank is used as a hot water tank, the rubber

pad is changed to GB5574-85, 4710 type heat-resistant rubber pad. The accessories of the water tank body are all galvanized to prevent corrosion.

The interior of the enamel water tank is clean and hygienic, white and beautiful, ensuring that the water quality is not polluted. Durable and sturdy, reinforced plates and stainless steel tie bars are installed at the four plate connections to enhance the firmness and stability of the water tank. On site assembly of composite panels is convenient, fast, flexible, and adaptable. For the sake of our drinking water hygiene and physical health, many cement water tanks in the past have been converted into enamel water tanks. For cement water tanks, fiberglass water tanks, and other water tanks, the advantages of enamel water tanks are hygiene, non toxicity, strong corrosion resistance, complete reflection of sunlight to absorb heat, no growth of algae inside, and ensuring clean water quality at all times, providing a guarantee for the hygiene of our drinking water.