Prefabricated Buried Water Tank

Basic concept of prefabricated buried water tank:

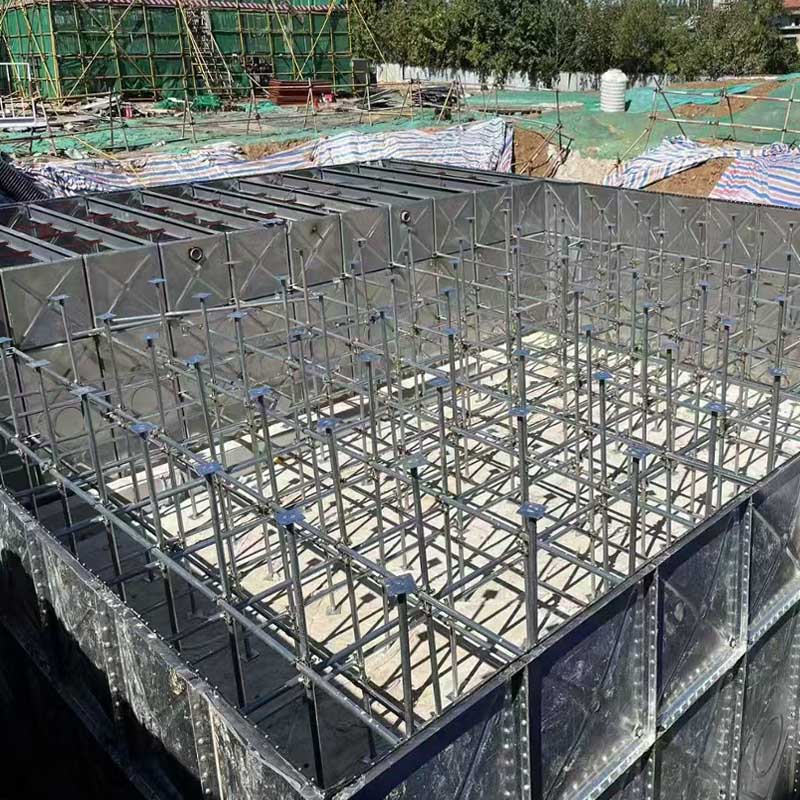

Prefabricated underground water tank is an underground water storage equipment that adopts modular design and on-site assembly. The main material is usually For composite materials of stainless steel and galvanized steel sheet (BDF) or SMC (fiberglass), assembled by bolt connection Cheng. Its core characteristics are space saving, fast construction, environmental protection and durability, widely used in fire protection, domestic water supply Commercial buildings and other fields. Anti floating buried water tanks can be placed under public green belts, which not only does not affect the effective green area, but also saves resources. Dafeng Company has been specializing in water tanks for many years, with experienced technicians, excellent water tank quality, and meticulous after-sales service provided to customers.

Modular design: The water tank is assembled from prefabricated standard modules (such as BDF composite panels) through bolt connections, supporting free combination to meet different capacity and size requirements, with high flexibility.

Material: Typically, a composite of stainless steel plate and galvanized steel plate (BDF plate) is used. The inner layer is made of stainless steel to ensure water quality, while the outer layer is made of galvanized steel plate to enhance structural strength.

Process: The module is precision stamped and formed, and there is no need for welding on site, making installation quick. The anti floating buried water tank has many advantages, such as light weight, high strength, corrosion resistance, high temperature resistance, clean water quality, anti-seepage, earthquake resistance, no moss growth, no secondary pollution of water quality, easy installation, no need for maintenance, and easy cleaning.

A brief overview of anti floating buried water tanks:

Anti floating buried water tank is a water storage facility designed specifically for underground environments, whose core function is to resist the destructive effects of groundwater buoyancy on the tank body through sophisticated engineering structures. This type of water tank is usually made of high-strength concrete or fiberglass material casting, and its structure is like a deeply rooted root system. It forms a dynamic balance system of "gravity resistance" through multiple technical means such as self weight anchoring, anti floating piles or counterweights. When the groundwater level rises sharply during the rainy season, the pressure relief holes preset at the bottom of the water tank and the waterproof coating on the side walls form a dual defense line, which can not only guide the seepage water pressure, but also prevent buoyancy accumulation - this "combination of dredging and blocking" engineering philosophy enables it to maintain

millimeter level structural stability under extreme hydrological conditions.

From the perspective of fluid mechanics, anti floating design can be regarded as the mechanical art of underground engineering: the thickness of the soil covering the top of the box needs to be accurately calculated .At the centimeter level, ensure precise offsetting of overlying loads and groundwater uplift forces; The arrangement density of

circumferential prestressed steel bars is as follows A protective net interwoven with latitude and longitude can increase the tensile strength of concrete by 3-5 times; And the raft foundation used for the box and foundation bottom plate

The foundation and concrete sealing reserved groove hook create a shear resistance that exceeds 200% of traditional welding processes. In high water level areas along the coast, engineers will also implant intelligent monitoring systems to track buoyancy changes in real time through differential pressure sensors. The data accuracy can reach ± 0.01MPa, ensuring automatic triggering of the heavy water injection mechanism during special working conditions

such as typhoon season.