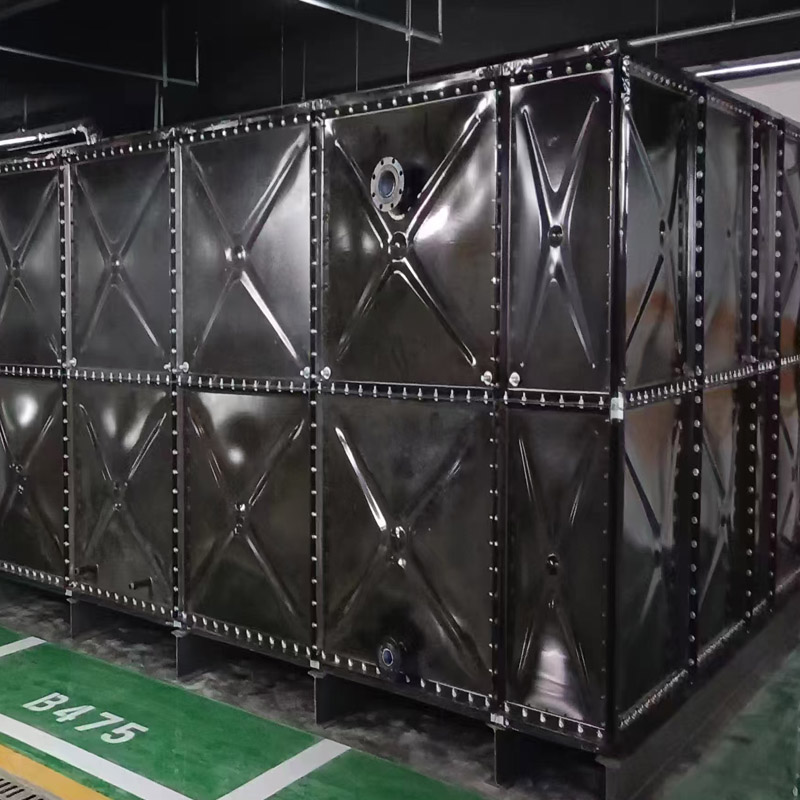

Enamel Water Tank

Basic introduction of enamel water tank:

Enamel steel plate water tank is a new type of water tank that uses HSC series porcelain glaze as the base glaze and surface glaze coated on δ 2- δ 5 steel plates, and the plates are assembled after firing. The mechanical impact resistance strength of its porcelain layer is 4-5 times higher than that of ordinary daily enamel vessels, and it is acid resistant, alkali resistant, non permeable, and leak proof, making it a new process for water tank anti-corrosion. Its performance indicators comply with national industry standards, water quality standards and food hygiene standards in China's regulations. The use of enamel water tanks in water heater production is increasing in China. Enamel inner liners are becoming the mainstay of water heater inner liners due to their superior anti-corrosion performance, replacing other inner liners.

Characteristics of enamel water tank:

1. The interior of the enamel water tank is clean and hygienic, white and beautiful, ensuring that the water quality is not polluted; 2. Durable and sturdy, reinforced plates and stainless steel tie bars are installed at the four plate connections to enhance the firmness and stability of the prefabricated enamel water tank; 3. On site assembly of composite panels, convenient, fast, flexible, and adaptable; 4. Impact resistance and long service life; 5. Acid resistant, alkali resistant, and corrosion-resistant; 6. No leakage, no seepage, and good sealing performance; 7. Storing hot water is superior to other water tanks (requiring heat-resistant rubber strips); 8. The enamel water tank has a smooth and flat interior, making it easy to clean.

Production process of enamel water tank:

The quality of steel plates must be selected based on the requirements of forming (deformation, welding, etc.), coating process, and enamel products. The expansion coefficient of enamel is 32x10 negative seventh power. The carbon content of the selected board shall not exceed 0.08%. Manganese exists in steel, which increases the yield limit and strength limit of the steel, while reducing its elongation performance. Therefore, the higher the manganese content, the greater the required deformation force. For carbon steel, silicon and manganese are both residues of deoxidizers during smelting.

The presence of sulfides will greatly affect the microstructure of steel plates, promote the formation of striped structures, thereby reducing the plasticity and toughness of cost steel, that is, reducing the cost drawing performance, and causing bubbles and pores to appear in the ceramic layer. Phosphorus dissolved in ferrite can significantly reduce the plasticity of cost steel, while increasing its strength and hardness. The lower the phosphorus content of steel plates used for deep drawing, the better. (<0.06%). Titanium added to steel is very beneficial for enamel, as it can combine with various components in the enamel, thus increasing its density. When coating the inner liner of a water heater in one go (wet flow coating, wet spray coating, electrostatic powder coating), titanium steel is an ideal substrate.