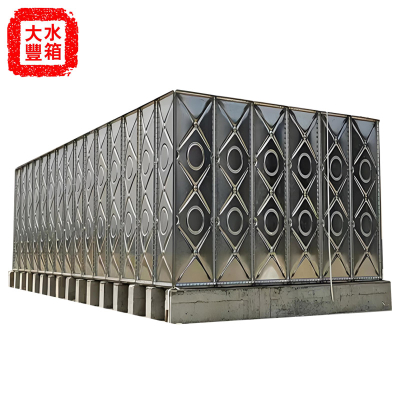

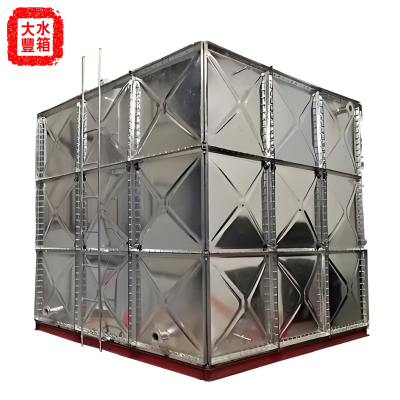

Stainless Steel Water Storage Tank

Dezhou Dafeng is an industrial company that integrates the production, design, and installation of various profile water tanks and cold water supply equipment. All products are sold directly by manufacturers at favorable prices, and the company has accumulated decades of successful experience in technical production processes. With a pragmatic and positive attitude, the company adapts to market development needs. With the platform of

"Dezhou - the hometown of fiberglass", we will continue to adhere to the business philosophy of "developing with virtue and seeking victory with trust". Guided by a scientific management model and advanced technological capabilities, we continuously strengthen our brand awareness, improve our product structure, strive for mutual benefit and win-win cooperation with our partners, and continuously meet customer needs.

Acceptance criteria for finished 304 stainless steel water storage tanks:

visual examination

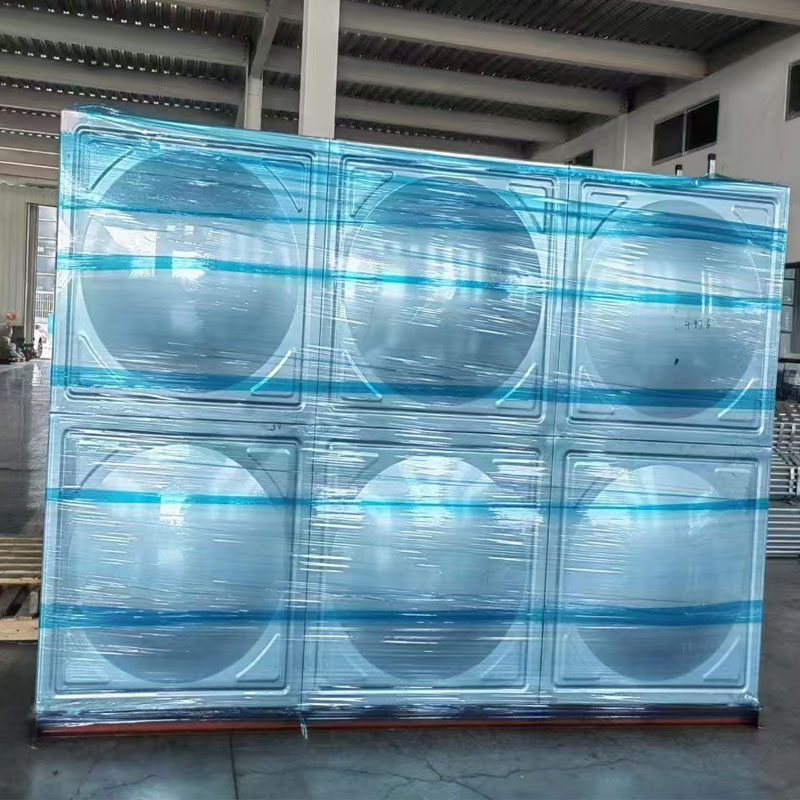

1. Surface flatness: Use a ruler and a feeler gauge to check the surface of the water tank, and the flatness deviation should be Not exceeding the prescribed range. Usually, it is required that the local flatness error within each square meter should

not exceed 5mm. The surface of the water tank should have no obvious unevenness to avoid affecting its appearance and subsequent use Cleaning during the process.For example, when inspecting a large 304 stainless steel water tank for domestic use, if large areas of protrusions or depressions are found on the surface, it will not only affect the appearance of the tank, but also May cause dirt accumulation when water accumulates, which is not conducive to the hygiene and maintenance of the water tank.

2. Color consistency: Observe the overall color of the water tank and ensure it is uniform and consistent. that is because

After normal processing and surface treatment, 304 stainless steel should exhibit a specific metallic color. in compliance

with If there is a significant difference in local color of the fruit, it may indicate the presence of material or surface treatment in that area Problem. For example, during the welding process, due to the influence of high temperature, some areas of stainless steel may become Changes occur, resulting in different colors.

3. Surface defects: Carefully inspect the surface of the water tank for scratches, cracks, sand holes, and other defects

Trapped. Scratches may damage the surface protective layer of stainless steel and reduce its corrosion resistance; Cracks will Seriously affecting the structural strength and sealing of the water tank; Sand holes may cause the water tank to malfunction during use Leakage phenomenon occurs. For minor defects, they can be inspected using tools such as magnifying glasses to ensure accuracy The surface quality of the water retention tank meets the requirements.

Dimensional inspection

1. Overall dimensions: According to the design drawings, use measuring tools (such as tape measures, calipers, etc.) to measure The length, width, and height dimensions of the water tank. The deviation between its actual size and the design

size should be within the allowable range, generally not exceeding ± 5mm. For large industrial 304 stainless steel water tanks, Accurate size control is particularly important as it may require installation in conjunction with other devices,

If the size deviation is too large, it may cause the inability to install properly or affect the operation of the entire system.

2. Wall thickness measurement: Use a thickness gauge to measure the thickness of the wall panel of the water tank. 304 not The wall thickness of the stainless steel water tank should meet the design requirements, and the wall thickness standards for water tanks of different specifications and uses should not be specified Same. For example, the thickness of the wall panels of ordinary domestic water tanks may be relatively thin, but it is also necessary to Must meet certain strength and pressure requirements; The wall thickness of the water tank used for storing corrosive liquids needs to be

To ensure its corrosion resistance and service life, it needs to be thicker. Measurements should be taken at multiple locations on the water tank wall Measure to ensure uniform wall thickness and compliance with design standards.